Brand :

LinengItem NO :

LN-T2000Compliance :

CE CertificatePayment :

Credit Card, Paypal, T/T , Western Union, LCWarranty :

Two Years Limited Warranty With Lifetime SupportDelivery Time :

In stockWhatsapp:

+86 18659217588WeChat:

18659217588Email:

cassie@lionbatterymachine.com-40℃ 80L Programmable constant temperature and humidity chamber

Overview

This series of programmable constant temperature and humidity chambers are suitable for the reliability test of various products. It has the characteristics of temperature control accuracy and wide control range. Performance indicators meet the requirements of "Testing methods for basic parameters of product environmental testing equipment: low temperature, high temperature, constant damp heat, alternating damp heat test equipment".

Performance

Note: When the ambient temperature is 25℃, the performance is measured after stabilization under no test load.

In addition, the temperature rise and fall time refer to the performance measured when the power supply voltage is normal and the ambient temperature is +25°C.

Temperature range | -40 ℃~150 ℃ |

Temperature fluctuation | ± 1.0 ℃ |

Uniform temperature | ± 2.0℃ |

The lowest temperature | -40 ℃ |

Heating time | 0~100℃ 25min approx. (non-linear) |

Cooling time | 0~-40℃ 50min approx. (non-linear) |

Humidity range | 20%~98% |

Humidity fluctuation | ± 1.5% |

Uniform humidity | ±3% |

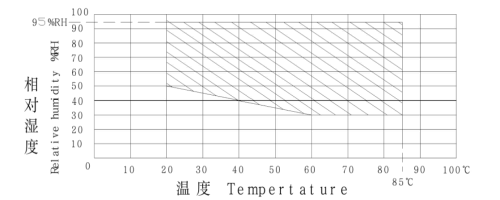

Temperature and humidity control range (as pic shown below) :

Chamber structure parameters

Inner box size | W 400 × H 500 × D 400mm |

Outer box size | According to the actual model |

Inner box material | Stainless steel plate |

Outer box material | Stainless steel plate |

Chamber door | 1. Single-piece door, left open, handle on the right 2. The three-layer vacuum layer of the product observation window |

Specimen rack | Stainless steel rack |

Test hole | One test hole ¢50mm on the left side of the body, one stainless steel hole cover |

Test body | SUS#304L stainless steel PT 100Ω platinum resistance 2 pcs (Taiwan) |

Insulation material | High-efficiency polyurethane foam + glass rock wool |

Heating system | Finned radiator tube stainless steel electric heater |

Control system

Touch control | Original Korean TEMI touch screen programmable controller; |

Temperature measuring device | Imported PT100 platinum resistance temperature and humidity sensor. |

Cooling system

Compressor | French "Taikang" fully enclosed high-efficiency energy-saving pioneer |

Refrigerant | DuPont, USA, adopts green refrigerant with zero ozone coefficient |

Condenser | Air-cooled condenser (special customization) |

Evaporator | Fin type automatic load capacity adjustment (automatic switchover for dehumidification and cooling) |

Humidification system

1. Water requires RO reverse osmosis pure water or distilled water

2. Stainless steel electric steam generation method humidifier

3. 1 set built-in water tank

4. 1 set automatic water supply pump (automatically supply water from the lower water tank to the upper level)

5. 3 pcs Electronic liquid level switch

6. Water shortage alarm and water recovery device

Power and safety configuration

1. Test power supply: AC220V 50Hz

2. Maximum capacity: 4.5 KW

3. Maximum current: 23 A

4. Equipment placement: When placing the cabinet, the distance from the wall should be greater than 100 mm.

5. Temperature over-rise preventer (protect the tested product and test box)

Picture for reference

Quanzhou Lineng Mechinery and Equipment Co., Ltd is a technology-based enterprise, integrating R&D, manufacturing, sales and service. Our company has strong scientific research strength, including more than 20 senior mechanical and electrical engineers, 8 external experts and professors, and more than 160 front-line technical workers.