Brand :

LinengItem NO :

LN-RP600Compliance :

CE CertificatePayment :

Credit Card, Paypal, T/T , Western Union, LCWarranty :

Two Years Limited Warranty With Lifetime SupportDelivery Time :

In stockWhatsapp:

+86 18659217588WeChat:

18659217588Email:

cassie@lionbatterymachine.comIntroduction

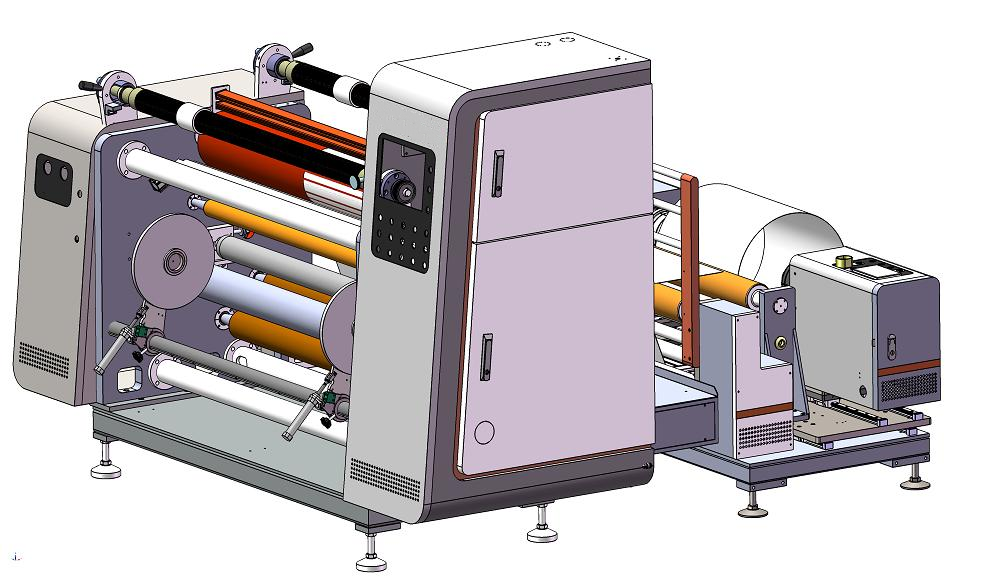

This equipment is mainly used for separator slitting and rewinding. After the transmission mechanism and the slitting mechanism, the required slitting and rewinding of the fixed width separator are realized, and the winding process is completed.

Installation requirement

Ambient temperature: 5 ~ 40℃;

Relative humidity: 20 ~ 50%;

Working environment: indoor, should ensure that the site air dry and smooth (no water and no oil)

Altitude: Less than 1000 meters.

Power supply: 3-phase 5-wire 380V, 50HZ, voltage fluctuation range: +8% ~ -8%; Total power 11kW;

Compressed air: after drying, filtering and pressure regulation: the outlet pressure is greater than 0.5MPa;

Basic specification

No | Item | Technical parameters | Note |

1 | Applicable substrate | PP/PE lithium-ion batteries separator | |

2 | Substrate thickness | 5-30 um | |

3 | Applicable substrate width | 200-550 mm | Roller surface width 600 mm |

4 | Slitting width | 50-500 mm | Depends on the material |

5 | Unwinding diameter | Dia400 mm | |

6 | Winding system | Surface center winding | |

7 | Unwinding system | Active constant tension release system | |

8 | Slitter system | Knife suspended front cut | |

9 | speed | Knife suspended front cut Mechanical speed 200m/min | Depends on the material |

10 | Slitting width accuracy | 0.2mm | |

11 | Control mode | PLC+ touch screen | |

12 | Width of waste edge slitting | >15 mm |

Unwinding specification

No | Item | Technical parameters | Note |

1 | Tension control system | With the motor and tension sensor to form a closed loop, constant tension winding, Unwinding tension 8N Min.-60N Max./±1N | |

2 | Correction mode | Automatic EPC control, stroke 140mm, with automatic left and right displacement function: with automatic micro-pendulum function | |

3 | Slight swing speed | 6-100m/min | |

4 | Slight swing stroke | Micro-pendulum and deviation correction are not used at the same time: micro-pendulum stroke ±25mm When the micro pendulum and correction are used at the same time: the micro pendulum stroke is ±3mm | |

5 | Unwinding correction accuracy | ±0.2 mm | |

6 | Winding method | Use 3/6 inch shaftless inflatable chuck to tighten; Roll can be simultaneously Implement volume up and volume down. | |

7 | Maximum winding diameter | Maximum diameter of winding roller: dia400 mm | |

8 | Maximum bearing capacity of the inflatable shaft | 100kg |

Winding specification

No | Item | Technical parameters | Note |

1 | Winding arm | 3 inch plate inflatable shaft winding | |

2 | Winding adjustment device | Adopt cylinder pressure or buffer, adjust the air pressure of the winding arm according to needs, and the winding side is neat. | |

3 | Driving roll | High precision polyurethane rubber roller, the hardness of Shore 65~70 degrees | |

4 | Winding power | Surface center winding | |

5 | Tension control | The winding tension is controlled by servo motor | |

6 | Maximum winding diameter | φ330 mm | |

7 | Static eliminator | Ion-air electrostatic eliminator eliminates diaphragm static electricity | |

8 | Edge closing mechanism | Side winding mechanism (two sets of independent arms) Minimum width of side material: 15-25mm; Coil diameter of side material: maximum coil diameter 200mm when the width of side material is 15-25mm; The maximum roll diameter is 330mm when the width of the side material is 25-100mm; |

Machine Configuration Table

Electrical parts

No | Item | Technical parameters | Note |

1 | Man-machine interface | 10 inch Wiren touch screen (1) | |

2 | PLC | Mitsubishi /LS(1) | |

3 | Unwinding servo motor (1 set) Traction servo motor (1 set) Winding servo motor (2 sets) | Wacoda /LS(4 sets) | |

4 | Correction system actuator | Bianfu (1 set) | |

5 | Tension sensor | Hongrui/Puliyuan (2) | |

6 | Static eliminator | Xinpu /kapper(1 set) |

Machine’s specification

No | Item | Technical parameters | Note |

1 | Winding arm | 2 sets (including two 3-inch inflatable shafts) | |

2 | Cut components with a straight knife | A set | |

3 | Side material independent arm | Two sets | |

4 | Unwinding clamp head | 3/6 inch share (1 set) | |

5 | Active winding rubber roller | 1 piece (material, imported polyurethane, Shore hardness 65-70 degrees) | |

6 | Active pull aluminum roller | 4 (Material, Aluminum 6063, hardened anode, | |

7 | Edge material winding rubber roller | 1 piece (material, imported polyurethane, Shore hardness 65-70 degrees) | |

8 | Passive aluminum roller | 7 (Aluminum 6063, hardened anode) | |

9 | Flattening roller | Curved roll (1 piece) | |

10 | Pneumatic element | Artac /SMC | |

11 | Rolling element | Japan NSK/NTN, E-class bearing |

Accessories

No | Name | Specification | Quantity | Note |

1 | Cutter weight | 50/20/10/5/2/1/0.5/0.2 mm | 10 pcs each unit | |

2 | Crimping roller | 30mm | 1 pcs | |

3 | Open end wrench | 8-piece set | 1 set | |

4 | Toolbox | 345*155*155mm iron toolbox | 1 pcs | |

5 | Hex wrench | 9-piece set | 1 set |

Picture for reference

Quanzhou Lineng Mechinery and Equipment Co., Ltd is a technology-based enterprise, integrating R&D, manufacturing, sales and service. Our company has strong scientific research strength, including more than 20 senior mechanical and electrical engineers, 8 external experts and professors, and more than 160 front-line technical workers.