Brand :

LinengItem NO :

LN-JLB-10Compliance :

CE CertificatePayment :

Credit Card, Paypal, T/T , Western Union, LCWarranty :

Two Years Limited Warranty With Lifetime SupportDelivery Time :

In stockWhatsapp:

+86 18659217588WeChat:

18659217588Email:

cassie@lionbatterymachine.com

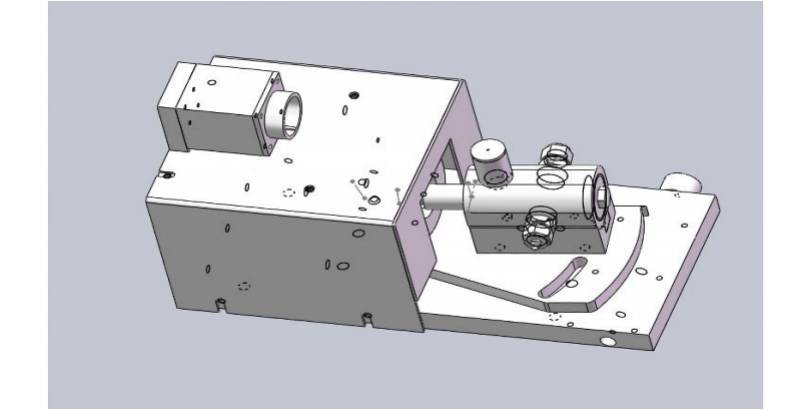

Working principle

Rotary valve liquid injection pump is a power transmission device that converts electrical energy into liquid kinetic energy. The ceramic plunger is driven by the rotation of the stepping motor to make it rotate and reciprocate in a directional direction. The liquid is drawn into the cavity through the liquid inlet in a quantitative manner, and then the liquid is pushed out of the cavity through the liquid outlet, and injected into the equipment required by the user through the pipeline Or in the product.

Features

3.1 High measurement accuracy

After repeated tests with water, oil, electrolyte and other fluids, the repeatability of the metering accuracy of our liquid injection pump can reach within ±0.25%.

3.2 Perfect control function and easy operation

The touch screen has a man-machine interface with digital buttons for convenient parameter setting and status monitoring; complete application functions, single-step or continuous operation of the injection pump, interval times and stop functions, and emergency stop, forward and reverse, fault detection, and others Equipment control operation and other functions. The perfect function can better meet the needs of customers and improve the utilization efficiency of the liquid injection pump.

3.3 Simple installation and low noise in use

Due to the stepping motor drive method, it is stable and reliable, with little noise interference and can be used only with mains power (AC 220v).

3.4 Wide application range

Especially in some environments that are easy to crystallize, general liquid injection pumps often fail to work normally because of crystal jams or increased rotation resistance. Our precision electric injection pump adopts stable and reliable components and complete program development, which can complete a complete cycle of steps in the case of large crystallization resistance or sudden freezing. So as to be more able to cope with the harsh environment and create more value for customers.

3.5 Maintenance is quite simple

Our company uses a special high wear-resistant ceramic pump head with long service life; if the liquid injection pump needs a long time before it is not used, the electrolyte in the liquid injection pipe of the liquid injection pump should be discharged, and the pump head can be cleaned with DMC.

|

Model |

Single head electric injection pump |

|

Type |

Rotating reciprocating positive displacement special ceramic injection pump |

|

Speed |

1-800rpm, according to system configuration and fluid characteristics for battery industry, 60-200rpm is best |

|

Stroke number |

1-9999 times, according to system configuration and fluid characteristics |

|

Filling range |

0-2.4ml adjustable |

|

Filling accuracy |

Within 3% |

|

Source voltage |

AC110V/220V, 50/60Hz single phase |

|

Power |

300W |

|

Dimension(L*W*H, mm) |

Controller box: 340*300*145 Filling device: 230*160*155 |

Hot Tags: laboratory electric filling machine, suppliers, manufacturers, factory, customized, price, discount, for sale, lab coating machine, Electric Hydraulic Press Machine, lithium ion battery vacuum glove box, cylindrical battery semi automatic grooving machine, cylindrical cell steel case grooving machine, 50ml Battery Electrolyte Filling Machine

Quanzhou Lineng Mechinery and Equipment Co., Ltd is a technology-based enterprise, integrating R&D, manufacturing, sales and service. Our company has strong scientific research strength, including more than 20 senior mechanical and electrical engineers, 8 external experts and professors, and more than 160 front-line technical workers.