Brand :

LinengItem NO :

LN-ZDCK-02CCompliance :

CE CertificatePayment :

Credit Card, Paypal, T/T , Western Union, LCWarranty :

Two Years Limited Warranty With Lifetime SupportDelivery Time :

In stockWhatsapp:

+86 18659217588WeChat:

18659217588Email:

cassie@lionbatterymachine.com1.Description

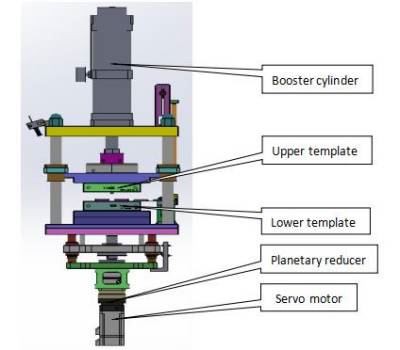

The single-station molding machine adopts mechatronics control, PLC and servo motors accurately control the depth of the punching shell, and use the touch screen to set, adjust and operate related parameters. This makes the operation of the machine and equipment simpler and more accurate! The equipment uses a gas-liquid booster cylinder. The gas-liquid booster cylinder uses the principle of gas-liquid boosting to convert a smaller air source pressure into a larger boost pressure, compress the upper and lower templates, and use a servo motor to connect with precision planetary deceleration Drive and push the mold core to form the aluminum-plastic film; the pressurizing pressure can be adjusted through the panel pressurized air source pressure regulating valve, and the punching depth can be adjusted by directly inputting parameters through the touch screen. The operation is very convenient. Equipped with safety light curtains, access control switches, and dual-button start switches, it is safe, convenient, efficient, and has a long service life; customers can provide their own molds to stamp various battery models of aluminum-plastic films to meet process requirements.

The equipment mainly includes five parts:

1.1Punching part

2.Basic configuration

No. | Name | Description | Note |

1 | Upper punching part | 1. The upper punching is driven by a pressurized cylinder, the punching stroke is 100mm, and the punching stroke is adjustable from 10-80mm | |

| 2. The pressing force is adjusted by the barometer, the theoretical punching output is 10 tons | |||

| 3. Pressurization stroke distance: 10mm | |||

| 4. The maximum opening height of the upper and lower templates is 80mm | Easy to clean and replace molds | ||

| 5. The punching part is precisely positioned by four linear bearings and matched with a wear-resistant high-frequency guide rod to drive the upper platen to move up and down. | |||

2 | Lower punching part | 1. Driven by Hechuan 1.5KW servo motor connected with 10:1 high-precision planetary reducer | The connection part adopts a high-precision screw with a pitch of 5mm and a diameter of 40mm |

| 2. Positioning adopts φ28mm high-precision dense steel ball guide column, which cooperates with the guide sleeve to move up and down. | |||

| 3. Adjust the punching depth value through the touch screen, 1-20mm adjustable | |||

| 4. Theoretical punching output is 2 tons. | |||

3 | Rack part | 1. The lower frame is welded by square pass, the surface is pickled, and the appearance defaults to the computer white paint | The color can be customized |

| 2. The door panel and aluminum profile are assembled | |||

| 3. The upper frame has a safety door | |||

| 4. The equipment is equipped with a universal upper and lower mold fixing plate; | |||

| 5. The hood is made of aluminum alloy and cold-rolled plate materials, and the default computer white paint | The color can be customized | ||

| 6. The upper frame opens the door with an access switch protection device | More humane and ensure safety | ||

| 7. Adopt four (M16) metal adjustable feet | Adjustable within the range of balance | ||

4 | Circuit part | Mitsubishi PLC | |

| Touch screen | |||

| The electromagnetic valve | |||

| Intermediate relay |

3.Basic parameters

No. | Item | Specification | Note |

1 | Adjustable stroke range of upper punching | 10-80mm | |

2 | Effective stroke of down servo punching | 20mm | |

3 | Main steel components | 45# steel | Hard chrome plating |

4 | Upper plate thickness | 48mm | |

5 | Flatness | <0.05mm | |

6 | Cutter width | 280mm | |

7 | Rated voltage | AC220V/50Hz | |

8 | Rated power | 2.5KW | |

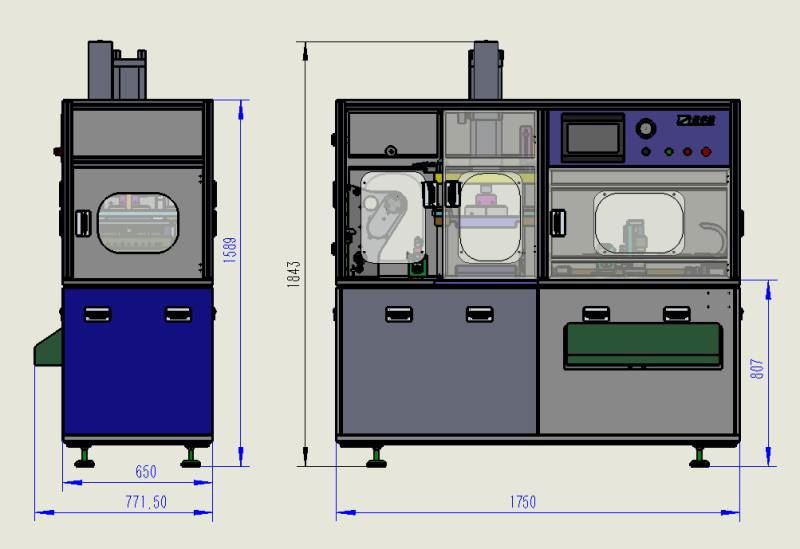

9 | Dimensions | L1750mm*W650mm*H1850mm | The specific size is subject to the actual product |

10 | Weight | 450kg | The specific weight is subject to the actual product |

4.Process parameters

No. | Item | Specification | Note |

1 | Effective working area | 400*400 mm | Mold size<effective working area |

2 | Production capacity | About 5-25pcs/min | Length within 100mm |

3 | Counting function | Real-time capacity counting function | |

4 | Suitable for stretching depth | ≤8mm | Single pit |

5 | Equipment utilization rate | ≥98% | |

6 | Rate of qualified products | ≥99.5% | |

7 | Maximum unwinding size | Φ280mm, width: 250mm |

5.Appearance

6.Picture for reference

Hot Tags: automatic aluminum laminated film case forming machine, suppliers, manufacturers, factory, customized, price, discount, for sale, Laboratory Equipment, Lab Battery Short Circuit Testing Machine, Heat Calender Machine, cylindrical battery case grooving machine, Hydraulic Press Mold, electrode roll to roll coater

Quanzhou Lineng Mechinery and Equipment Co., Ltd is a technology-based enterprise, integrating R&D, manufacturing, sales and service. Our company has strong scientific research strength, including more than 20 senior mechanical and electrical engineers, 8 external experts and professors, and more than 160 front-line technical workers.