Brand :

LinengItem NO :

LN-PCPLCompliance :

CE CertificatePayment :

Credit Card, Paypal, T/T , Western Union, LCWarranty :

Two Years Limited Warranty With Lifetime SupportDelivery Time :

In stockWhatsapp:

+86 18659217588WeChat:

18659217588Email:

cassie@lionbatterymachine.comI. Introduction

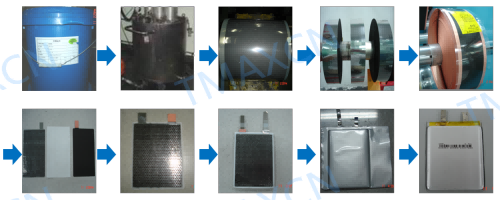

Pouch cell is a flexible and lightweight rechargeable battery. It features a flat, pouch-like package that holds the battery's active components. Pouch cells offer advantages such as high energy density, flexible form factor, excellent power delivery, lightweight design, improved thermal characteristics, and longer cycle life. These qualities make pouch cells a preferred choice for applications in portable electronics, electric vehicles, and renewable energy systems.

II. Machine list

NO. | Process | Item name |

1 | Cathode mixing | Vacuum mixer |

2 | Anode mixing | Vacuum mixer |

3 | Slurry feeding | Slurry feeding system |

4 | Cathode coating | Slot die coater |

5 | Anode coating | Slot die coater |

6 | NMP recycling | NMP recycling system |

7 | Cathode electrode rolling press | Roller Press |

8 | Anode electrode rolling press | Roller Press |

9 | Cathode slitting | Automatic slitting machine |

10 | Anode slitting | Automatic slitting machine |

11 | Cathode die cutting | Automatic die cutter |

12 | Anode die cutting | Automatic die cutter |

13 | Stacking | Automatic stacking machine |

14 | Hot press test | Hot press testing machine |

15 | Case forming | Case forming machine |

16 | Sealing | Top and side sealing machine |

17 | Drying | Vacuum oven |

18 | Filling | Automatic electrolyte filling machine |

19 | Formation | Hot press formation machine |

20 | final sealing | Final sealing machine |

21 | Grading | Grading cabinet |

22 | Power auxiliary | Dehumidification system |

23 | Vacuum pump | |

24 | Air compressor | |

25 | Deionized water machine |

III. Plant display

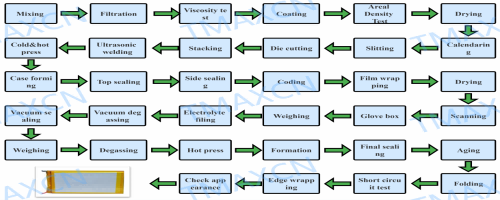

IV. Production process

TMAX follows a comprehensive procurement process to ensure a seamless experience for our customers.

Initial Consultation: We have an in-depth discussion with the customer to understand their battery production requirements, machine specifications, and budget constraints.

Proposal Preparation: Based on the consultation, we create a detailed proposal that outlines our recommended battery-making machines, pricing, delivery timelines, and additional services or support.

Proposal Presentation: We present the proposal, highlighting the features and benefits of our machines, addressing customer questions, and explaining how our solution meets their needs.

Negotiation and Agreement: We engage in negotiations to address concerns and modify the proposal if needed, aiming to reach a mutual agreement on pricing, terms, and conditions.

Purchase Order: The customer issues a purchase order (PO) that formalizes the agreement, specifying quantities, prices, delivery dates, and contractual obligations.

Order Fulfillment: We manufacture or source the battery-making machines according to agreed specifications, conducting quality control checks to ensure high performance and reliability.

Shipment and Delivery: We handle packaging, transportation, and customs clearance, providing tracking information and updates on the shipment's status.

Installation and Training: Our technicians offer installation services and comprehensive training on machine operation, maintenance, and troubleshooting.

Post-Sales Support: We provide ongoing customer support, including assistance with spare parts, maintenance, upgrades, and expansions, to ensure customer satisfaction.

By following this streamlined procurement process, we deliver high-quality battery-making machines tailored to our customers' requirements while providing excellent support throughout their lifecycle.

VI. Manufacturing Cycle and Planning

Product Description

Hot Tags: pouch cell manufacturing production equipment, suppliers, manufacturers, factory, customized, price, discount, for sale, battery stacking machine, cold rolling press machine, slot die coater, Cathode Active Materials, Battery Testing Machine, vacuum glove box

Quanzhou Lineng Mechinery and Equipment Co., Ltd is a technology-based enterprise, integrating R&D, manufacturing, sales and service. Our company has strong scientific research strength, including more than 20 senior mechanical and electrical engineers, 8 external experts and professors, and more than 160 front-line technical workers.