Brand :

LinengItem NO :

LN-6009DCompliance :

CE CertificatePayment :

Credit Card, Paypal, T/T , Western Union, LCWarranty :

Two Years Limited Warranty With Lifetime SupportDelivery Time :

In stockWhatsapp:

+86 18659217588WeChat:

18659217588Email:

cassie@lionbatterymachine.com1. Relevant standard test requirements

1.1 The test object is a complete vehicle or a complete vehicle-mounted lithium-ion battery system or a vehicle-mounted lithium-ion battery system subsystem including lithium-ion batteries and electrical connections

1.2 Test conditions

The test should be carried out under the following conditions:

A) This test should be carried out in an environment where the temperature is above 0°C, the relative humidity is 15% to 90%, and the atmospheric pressure is 86 to 106 kPa.

B) Before the start of the test, the SOC of the test object should be adjusted to be greater than [90% or 95%] of the normal SOC working range specified by the manufacturer.

C) Before the start of the test, all test devices must be in normal operation.

D) The test should make as few changes to the test sample as possible, and the manufacturer shall submit a list of the changes made.

E) The test should be carried out in an indoor environment or an environment where the wind speed is not greater than 2.5km/h

1.3 Thermal runaway trigger object

Two methods, heating and acupuncture, are recommended as candidate methods for thermal diffusion test of lithium-ion battery system. Manufacturers can choose one of them.

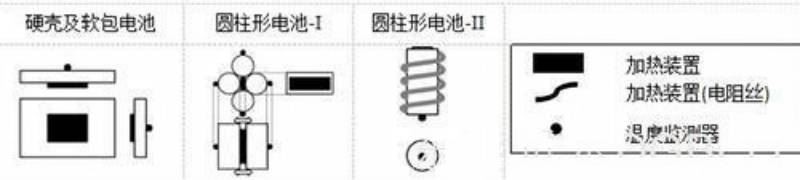

1.4 Heating trigger thermal runaway:

Use flat or rod-shaped heating device, and its surface should be covered with ceramic, metal or insulating layer. For the block heating device with the same size as the lithium ion battery, the heating device can be used to replace one of the lithium ion batteries and directly contact the surface of the trigger object; for the thin film heating device, it should always be attached to the surface of the trigger object; Whenever possible, the heating area of the heating device should not be larger than the surface area of the lithium-ion battery; if the heating surface of the heating device is in direct contact with the battery surface, the location of the heating device should correspond to the location of the temperature sensor specified in 1.6; After the installation is complete, immediately start the heating device to heat the trigger object with the maximum power of the heating device; the power requirements of the heating device are shown in Table A.1, but it is not mandatory; when thermal runaway occurs or the temperature at the monitoring point defined in 1.6 When it reaches 300℃, stop triggering.

Table A.1: Power selection of heating device

Test object energy E (Wh) | Maximum power of heating device (W) |

E<100 | 30-300 |

100≤E<400 | 300-1000 |

400≤E<800 | 300-2000 |

E≥800 | >600 |

1.5 The manufacturer judges whether thermal runaway occurs based on one or more of the following conditions, and at the same time, it is necessary to indicate the conditions for judging thermal runaway in the technical document.

a) The test object has a voltage drop;

b) The temperature of the monitoring point reaches the maximum operating temperature specified by the manufacturer;

c) The temperature rise rate of the monitoring point;

d) Other status parameters defined by the manufacturer.

1.6 Monitoring of voltage and temperature

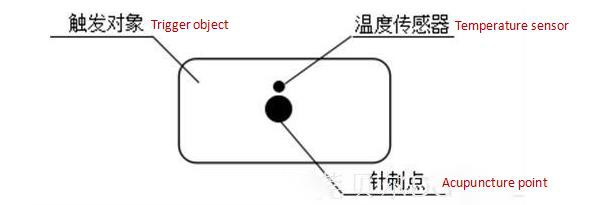

Figure A.1 Schematic diagram of the layout position of the temperature sensor when acupuncture is triggered

Monitor the voltage and temperature of the trigger object to determine whether thermal runaway occurs. When monitoring the voltage, the original circuit should not be changed. The monitoring temperature is defined as temperature A (the highest surface temperature of the trigger object during the test). The sampling interval of temperature data should be less than 1s, the accuracy requirement should be ±2℃, and the diameter of the temperature sensor tip should be less than 1mm.

When acupuncture is triggered, the position of the temperature sensor should be as close as possible to the short-circuit point.

When the heating is triggered, the temperature sensor is arranged on the side away from the heat conduction, that is, installed on the opposite side of the heating device (see Figure A.2). If it is difficult to install the temperature sensor directly, place it in a position where it can detect the continuous temperature rise of the trigger object.

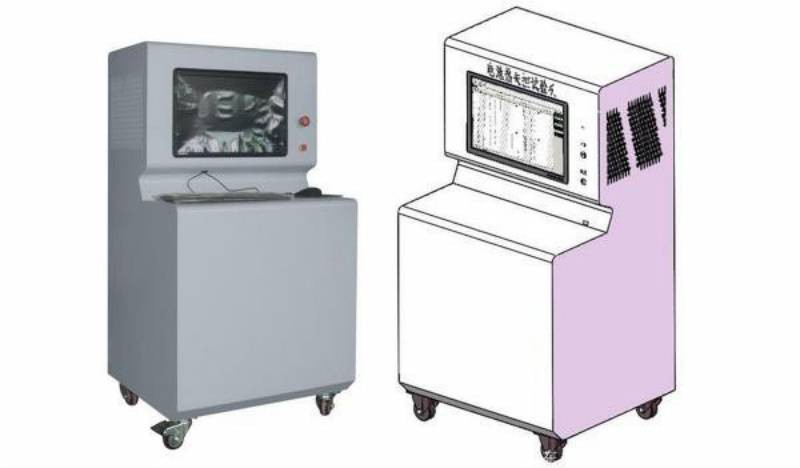

2.Main technical parameters

Model | 6009D |

Trigger mode | overcharge and heating modes are optional |

Number of heating mode channels | 2 channels (one channel is commonly used, the other channel is reserved) |

Maximum heating power | 3KW, single channel |

Power adjustment method | Replace heating tube with different power + adjust input current |

Heating voltage | AC 220V, 50HZ |

Maximum overcharge voltage | 10V and 100V two gears |

Voltage acquisition channel | 10 channels, 20 channels, 40 channels are optional |

Temperature acquisition channel | 10 channels, 20 channels, 40 channels are optional |

Control method | PLC+PC control (PC and host integrated) |

Overall dimensions of control host | W700 X D650X H1360 MM |

Explosion-proof box | W2000XD3000XH2000MM (optional) |

Total equipment weight | 1000kg |

Equipment power supply | AC220V 7KW |

3.Picture for reference

Hot Tags: battery thermal runaway testing machine, suppliers, manufacturers, factory, customized, price, discount, for sale, laboratory calendering machine, 18650 automatic grooving machine, electrode roll to roll coater, Electrode Roller Press Machine, polymer battery production line, doctor blade coating machine

Quanzhou Lineng Mechinery and Equipment Co., Ltd is a technology-based enterprise, integrating R&D, manufacturing, sales and service. Our company has strong scientific research strength, including more than 20 senior mechanical and electrical engineers, 8 external experts and professors, and more than 160 front-line technical workers.