Brand :

LinengItem NO :

LN-HWHS40Compliance :

CE CertificatePayment :

Credit Card, Paypal, T/T , Western Union, LCWarranty :

Two Years Limited Warranty With Lifetime SupportDelivery Time :

In stockWhatsapp:

+86 18659217588WeChat:

18659217588Email:

cassie@lionbatterymachine.comOverview

This series of programmable constant temperature and humidity chambers are suitable for the reliability test of various products. It has the characteristics of temperature control accuracy and wide control range. Performance indicators meet the requirements of "Testing methods for basic parameters of product environmental testing equipment: low temperature, high temperature, constant damp heat, alternating damp heat test equipment".

Performance

Note: When the ambient temperature is 25℃, the performance is measured after stabilization under no test load.

In addition, the temperature rise and fall time refer to the performance measured when the power supply voltage is normal and the ambient temperature is +25°C.

Temperature range | -40 ℃~70 ℃ |

Temperature fluctuation | ± 0.5 ℃ |

Display accuracy | 0.01 ℃ |

The lowest temperature | -40 ℃ |

Heating time | 0 ~70 ℃ about 30min |

Cooling time | 0 ~-40 ℃ about 50min |

Humidity range | 30% ~95% |

Humidity fluctuation | ± 3.5% |

Display accuracy | 0.1% |

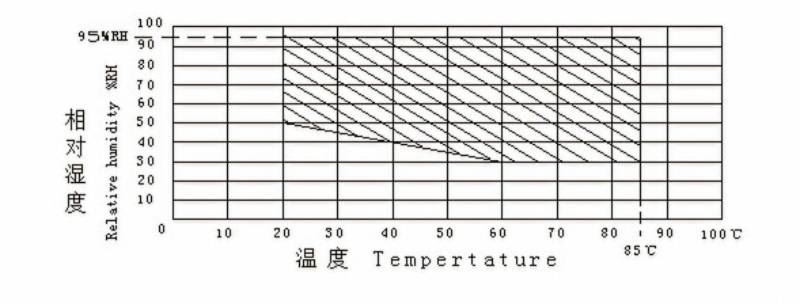

Temperature and humidity control range (as pic shown below) :

Chamber structure parameters

Inner box size | W 2000 × H 2000 × D 2000mm |

Outer box size | according to the actual model |

Inner box material | stainless steel plate |

Outer box material | cold plate paint |

Chamber door | 1.Single-piece door 2.The three-layer vacuum layer of the product observation window allows you to clearly observe the test conditions of the test samples in the box through the observation window. |

Test hole | One test hole ¢50mm on the left side of the body, one stainless steel hole cover, one silicone plug. |

Test body | SUS#304L stainless steel PT 100Ω platinum resistance 2 pcs (Taiwan) |

Insulation material | high-efficiency polyurethane foam + glass rock wool |

Heating system | finned radiator tube stainless steel electric heater |

Control system

Touch control | 1.Original Korean TEMI touch screen programmable controller; 2.Program storage capacity 120 groups; 3.With power-off program memory function, it will continue after power-on; 4.Cycle times up to 999 times. |

Temperature measuring device | Imported PT100 platinum resistance temperature and humidity sensor. |

Temperature measurement | Pt100 platinum resistance. |

Humidity measurement | Pt100 platinum resistance dry and wet bulb method. |

Control device | Programmable temperature and humidity controller South Korea TEMI880 touch screen. It can display setting parameters, time, heater, humidifier and other working status, and has the function of automatic test operation and PID parameter self-tuning. Only need to set the temperature to realize the automatic operation function of the refrigerator. The control system uses an intelligent control software system, with automatic combination of cooling, heating, humidification and other subsystems working conditions, so as to ensure high-precision control in the entire temperature and humidity range, and achieve the purpose of energy saving and consumption reduction. The perfect detection device can automatically perform detailed fault display and alarm. For example, when the test chamber is abnormal, the controller automatically displays the fault status. |

Screen display | Set temperature and humidity; measured temperature and humidity; heating, humidification, time, and other working status and various alarm indications. |

Display accuracy | Temperature: 0.01 ℃ Humidity: 0.1% R.H |

Program capacity | The total number of program segments is 120, 99 hours and 59 minutes; the program can be cycled, and the programs can be linked; |

Operation mode | Constant operation, program operation; |

Cooling system

Compressor | French "Taikang" fully enclosed high-efficiency energy-saving pioneer |

Refrigerant | DuPont, USA, adopts green refrigerant with zero ozone coefficient |

Condenser | Air-cooled condenser (special customization) |

Evaporator | Fin type automatic load capacity adjustment (automatic switchover for dehumidification and cooling) |

Expansion system | Refrigeration system controlled by capillary capacity |

Electromagnetic valve | American Changheng Lusi copper switch valve |

Refrigeration principle | The refrigeration part is the main part of the equipment that produces the cold source, which provides the required cooling capacity for the cooling, low temperature and constant temperature of the equipment. According to the different test conditions of the equipment, the refrigeration system is automatically turned on to provide the cooling capacity for the corresponding test process. The design of the refrigeration system uses energy adjustment technology. An effective treatment method can ensure that the energy consumption and cooling capacity of the refrigeration system can be adjusted under the normal operation of the refrigeration unit, so that the operation cost and failure of the refrigeration system The rate dropped to a more economical state. |

Refrigeration system components | Compressor: The core of the refrigeration system is the compressor. In this plan, we use the French Taikang fully enclosed compressor to form a set of refrigeration system to ensure the cooling requirements of the studio. |

Humidification system

1. Water requires RO reverse osmosis pure water or distilled water

2. Stainless steel electric steam generation method humidifier

3. 1 set automatic water supply pump (automatically supply water from the lower water tank to the upper level)

4. Water shortage alarm and water recovery device.

Power and safety configuration

1. Test power supply: AC380V 3Φ5 50Hz

2. Maximum capacity: 40 KW

3. Maximum current: 80 A

4. Equipment placement: When placing the cabinet, the distance from the wall should be greater than 100 mm.

5. Temperature over-rise preventer (protect the tested product and test box)

6. High-speed circuit protector (protect heating,)

Hot Tags: Low Temperature And Humidity Chamber, suppliers, manufacturers, factory, customized, price, discount, for sale, automatic layer by layer stacking machine, automatic stacking machine, Sliver Foam, Button Battery Crimping Machine, Porous Aluminum Foam, Coin Cell Case

Quanzhou Lineng Mechinery and Equipment Co., Ltd is a technology-based enterprise, integrating R&D, manufacturing, sales and service. Our company has strong scientific research strength, including more than 20 senior mechanical and electrical engineers, 8 external experts and professors, and more than 160 front-line technical workers.